Equip your ESD zone properly

We show you how to equip your ESD protection zone correctly! Setting up an EPA (Electrostatic Protected Area) in which ESD-sensitive assemblies can be handled safely requires a well thought-out and comprehensive protection concept. The key points here are both internal and external protection of the assemblies as well as organisational measures that actively involve employees, visitors, suppliers and customers.

In order to realise a standard-compliant and efficient EPA, we take into account all relevant influencing factors: from the selection of suitable ESD materials and workplace equipment to safe earthing concepts and correctly coordinated flooring and packaging solutions. We also explain how clear processes, training and behavioural guidelines ensure that ESD protection is not only technically available, but is also consistently implemented in day-to-day operations.

With our expertise, we support you in setting up an EPA that sustainably protects your electronic assemblies, comprehensively increases production safety and at the same time creates the basis for reliable, high-quality end products.

Which ESD protection measures are necessary

To successfully comply with an effective ESD protection concept, it is essential to ensure that people and workstations within an EPA are always earthed and components are protected:

- Personnel earthing: As people are the main sources of electrostatic charge, wearing ESD wristbands, ESD shoes, ESD clothing and ESD gloves is particularly important

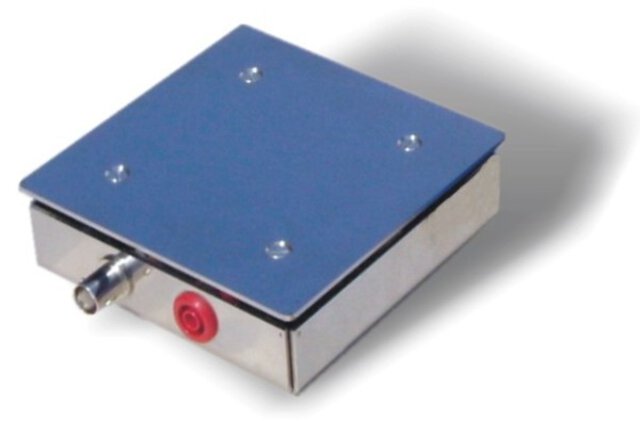

- Grounding the workplace: Every work table or work surface should be covered with ESD material and grounded using cables and grounding connections

- Protection of components: ESD-sensitive components should be stored and transported in antistatic containers or on antistatic mats. Only use ESD-compliant tools.

Organisational ESD protection measures

In addition to technical precautions, administrative and organisational measures are also crucial for effective ESD protection. These ensure that all processes comply with current standards and are implemented correctly. Important components are

- Training, workshops and regular briefings for all affected employees

- Appointment of a responsible ESD coordinator

- Introduction and maintenance of an ESD control programme

- Regular ESD measurements and documented inspections

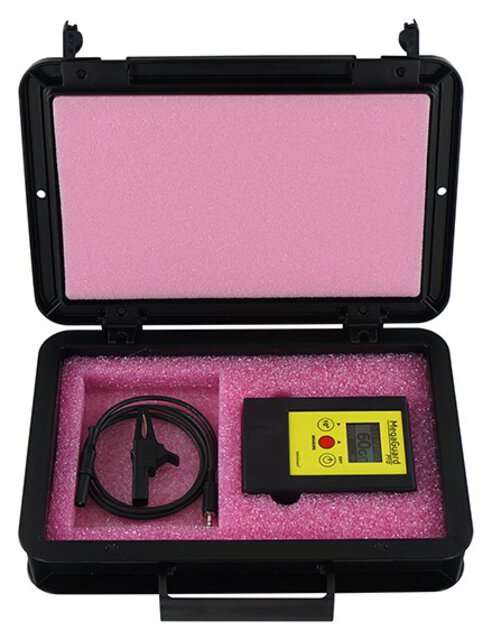

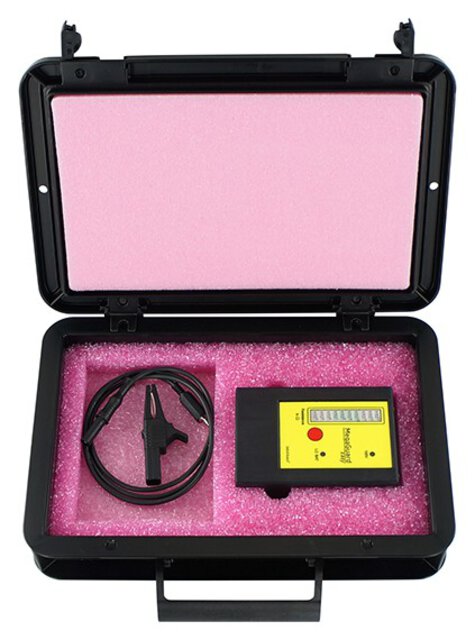

- Use of suitable test equipment for functional checks

- Carrying out internal ESD audits for quality assurance

Typical sources of error in ESD protection

- Missing or improper personal earthing: A common mistake is not wearing ESD wristbands or shoes - or their improper use.

- Inadequate earthing of workstations: Table mats, shelves or equipment surfaces are often made of ESD-suitable material, but are not always correctly earthed.

- Use of unsuitable materials: Paper pads, plastic boxes, standard adhesive tape or normal shipping packaging generate electrostatic charge.

- Inadequate storage and transport: Sensitive components are often transported or stored without suitable protective packaging. Moving from an ESD-safe environment to a non-protected zone can also be problematic.

- Incomplete training of employees: If employees do not know the importance of ESD protection or do not question incorrect behaviour, critical errors can quickly creep in on a day-to-day basis.

- Insufficient checks and documentation: If checks are missing or carried out too infrequently, problems can be recognised late or not at all.

Learn how to avoid such errors in our ESD training courses. You can learn many other exciting things about ESD protection in our ESD protection blog.

Our ESD table mat configurator

With our ESD table mat configurator, you can customise table mats to your individual requirements and have us manufacture them precisely to size. You are completely free to choose the size of your ESD table mat. There are three colours to choose from: platinum grey, light blue and black. All ESD mats are made from the same high-quality material, which has the following properties:

- Resistant to heat and solder

- Resistant to chemicals and oil

- Permanently elastic and abrasion-resistant

- RoHS-compliant

- Anti-reflective surface

- Two-layer structure (dissipative/conductive)

If you need special cut-outs for cables or other elements, you can choose between rectangular and oval shapes. Press studs can be individually positioned for earthing your desk mat.

Online training

ESD Basics

- Training duration: approx. 60 minutes

- Individual online course (no live appointment)

- Including extensive audio recording by Dirk Schwenner

- Training location: Online anytime and anywhere

- Single and multiple access bookable for several participants

On-site training

ESD Specialist

- 1 training day à 6h

- Number of participants: approx. 6 persons

- Lecturers: Dirk Schwenner | Marco Petrick

- Training locations: Weidinger GmbH, Gernlinden | DS SafetyWear GmbH, Lohmar

- Secure your place on the ESD specialist training course now!

On-site training

ESD Coordinator

- 2 training days à 6h

- Number of participants: approx. 6 persons

- Lecturers: Dirk Schwenner | Marco Petrick

- Training locations: Weidinger GmbH, Gernlinden | DS SafetyWear GmbH, Lohmar

- Secure your ESD coordinator training place now!

On-site training

Customised ESD training

- Individual time frame and customisable course content

- Number of participants by arrangement

- Lecturers: Dirk Schwenner | Marco Petrick

- On-site at your company / your training facilities

- Enquire about your individual ESD training course now, free of charge and without obligation!