ESD measurement

Do you already use an EPA in your company and would now like to ensure that all criteria for a standard-compliant ESD protection zone are met? Our ESD experts will support you and carry out a comprehensive ESD measurement in accordance with IEC / DIN EN 61340-5-1 directly in your production facility.

The professional evaluation of your existing EPA provides you with a transparent, standard-compliant assessment of your current protection level. We test all relevant elements such as workstations, earthing systems, floors, wrist straps, packaging materials and personal protective equipment. In this way, we identify possible weak points and show clearly comprehensible potential for optimisation.

Our detailed measurement reports not only serve as valuable evidence for internal and external audits, but also provide you with a solid basis for the further development of your ESD protection strategy. Thanks to our many years of expertise in electronics manufacturing, you benefit from practical recommendations that increase process reliability, reduce rejects and sustainably improve the overall quality of your products.

Types of ESD measuring devices

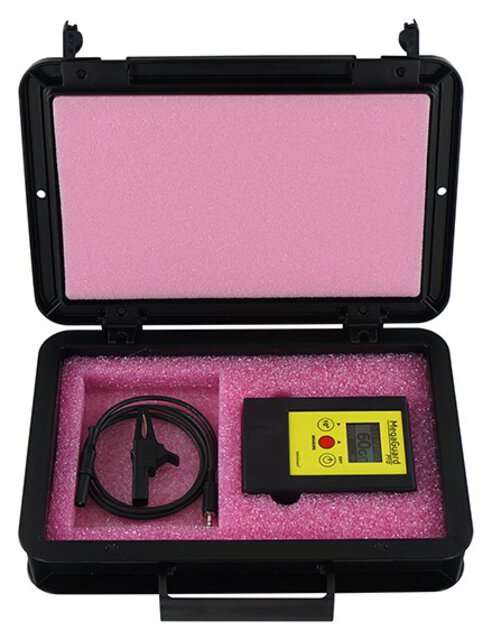

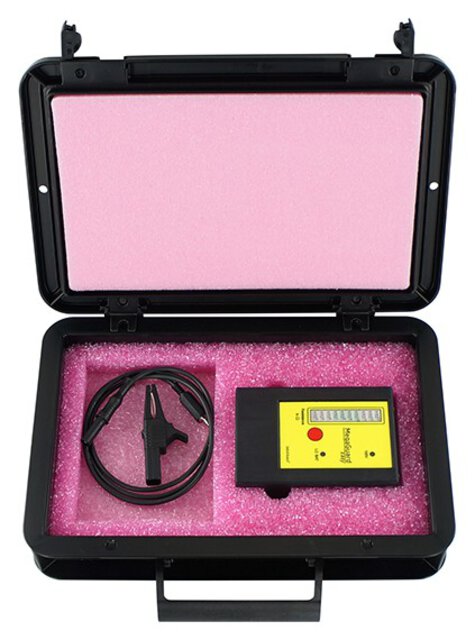

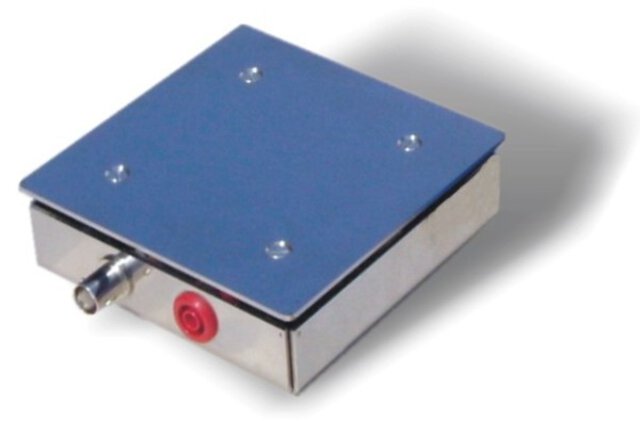

There are many different types of ESD measuring devices. With the devices from SafeGuard, we have a variety of different ESD measuring devices in our range:

- Earthing testers: earthing testers test the earthing resistance of people at the entrance to EPA areas to prevent ESD damage to electronic components.

- Walking tests: The walking test measures the electrostatic charge of a person walking on an ESD floor with ESD shoes to check the effectiveness of the discharge.

- High-ohm meter: A high-ohm meter measures the surface resistance of materials in order to reliably check the discharge capability and earthing properties of a product.

- Electric field meter: An electric field meter measures electric fields in the environment to detect the presence of electrostatic charges and assess their influence on sensitive systems.

ESD measurement procedure

Before the measurement:

- Telephone discussion or inspection of the production facility (depending on location) by arrangement. A schedule can then be drawn up.

On the day of the measurement:

- Inspection of production together with the production manager / ESD coordinator

- Measurement of all objects in the EPA - ESD packaging, ESD floor, ESD clothing, ESD coverings, etc. Naturally, the latest measurement technology is used here.

- Work processes only have to be interrupted briefly during the measurement, approx. 20 minutes per workstation

- Measured values are documented in a measurement protocol

Afterwards:

- Creation of a measurement log with position information in the production floor plan

- Follow-up measurement (in random samples) after one year (must be ordered separately)

Why is an ESD measurement useful?

An ESD measurement by our experts provides a reliable basis for evaluating and optimising your ESD protection. Precise on-site testing identifies electrostatic risks that can lead to damage to electronic components in sensitive production or storage areas. Our experts use calibrated measuring devices and document all relevant values in accordance with applicable standards. This allows weak points to be eliminated in a targeted manner and measures to improve conductivity to be implemented effectively. Regular ESD measurements not only increase process reliability, but also contribute to compliance with internal quality standards and external audit specifications.

Let our experts provide you with professional advice and assessment on ESD issues.

Are there standards for protection and measurement?

In Germany and many other European countries, the standard DIN EN 61340-5-1 is relevant here. Among other things, it deals with the "protection of electronic components against electrostatic phenomena" and is, so to speak, the basic element of our work. In the group of ESD control elements, emphasis is first placed on the ESD protection zones, i.e. the specific areas where electronics are used and ESD protection is therefore absolutely essential. However, administrative protective measures such as employee training and audits are also discussed here.

Online training

ESD Basics

- Training duration: approx. 60 minutes

- Individual online course (no live appointment)

- Including extensive audio recording by Dirk Schwenner

- Training location: Online anytime and anywhere

- Single and multiple access bookable for several participants

On-site training

ESD Specialist

- 1 training day à 6h

- Number of participants: approx. 6 persons

- Lecturers: Dirk Schwenner | Marco Petrick

- Training locations: Weidinger GmbH, Gernlinden | DS SafetyWear GmbH, Lohmar

- Secure your place on the ESD specialist training course now!

On-site training

ESD Coordinator

- 2 training days à 6h

- Number of participants: approx. 6 persons

- Lecturers: Dirk Schwenner | Marco Petrick

- Training locations: Weidinger GmbH, Gernlinden | DS SafetyWear GmbH, Lohmar

- Secure your ESD coordinator training place now!

On-site training

Customised ESD training

- Individual time frame and customisable course content

- Number of participants by arrangement

- Lecturers: Dirk Schwenner | Marco Petrick

- On-site at your company / your training facilities

- Enquire about your individual ESD training course now, free of charge and without obligation!