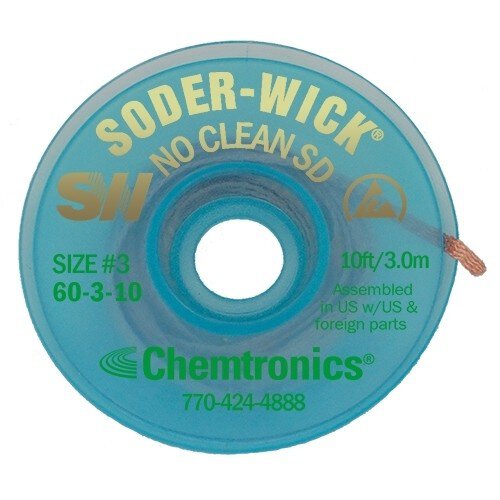

ESD desoldering braid Soder-Wick®, halogen-free

Soder-Wick® No Clean desoldering braid was developed to enable fast and safe desoldering without leaving harmful flux residues.

Soder-Wick® No Clean desoldering braid uses pure, oxygen-free copper braid and patented flux technology to produce an efficient and effective desoldering braid. Soder-Wick® No Clean desoldering braid is available on ESD-safe spools to prevent damage from static electricity.

The entire braid is sealed in a nitrogen purged package to prevent corrosion and loss of performance due to moisture and oxygen.

Features and benefits

• Soder-Wick® No Clean packaged in ESD-safe, static dissipative coils

• Minimizes the risk of damage from static electricity

• Patented, non-corrosive, halogen-free, organic no-clean flux

• Desolders up to 40% faster than comparable no-clean solder braids and leaves cleaner PCBs

• Meets Bellcore TR-NWT-000078 and ANSI IPC SF-818 for surface insulation resistance

Applications

• Soder-Wick® No Clean SD safely removes solder in all applications requiring ROL0 type fluxes

• BGA solder wire specifically designed for rework/repair of BGA pads and chips, allowing all BGA pads to be cleaned in three to four passes

Specifications

• MIL-F-14256 F

• NASA-STD-8739.3 Soldered electrical connections

• DOD-STD-883E, Method 2022

• ANSI/IPC J STD-004, Type ROL0

• Complies with MIL-STD-883B, Bellcore TR-NWT-000078, ANSI/IPC J SF-818

• Meets the solderability parameters tested by the Singapore Institute of Standards and Industrial Research (SISIR)

Soder-Wick® No Clean desoldering braid uses pure, oxygen-free copper braid and patented flux technology to produce an efficient and effective desoldering braid. Soder-Wick® No Clean desoldering braid is available on ESD-safe spools to prevent damage from static electricity.

The entire braid is sealed in a nitrogen purged package to prevent corrosion and loss of performance due to moisture and oxygen.

Features and benefits

• Soder-Wick® No Clean packaged in ESD-safe, static dissipative coils

• Minimizes the risk of damage from static electricity

• Patented, non-corrosive, halogen-free, organic no-clean flux

• Desolders up to 40% faster than comparable no-clean solder braids and leaves cleaner PCBs

• Meets Bellcore TR-NWT-000078 and ANSI IPC SF-818 for surface insulation resistance

Applications

• Soder-Wick® No Clean SD safely removes solder in all applications requiring ROL0 type fluxes

• BGA solder wire specifically designed for rework/repair of BGA pads and chips, allowing all BGA pads to be cleaned in three to four passes

Specifications

• MIL-F-14256 F

• NASA-STD-8739.3 Soldered electrical connections

• DOD-STD-883E, Method 2022

• ANSI/IPC J STD-004, Type ROL0

• Complies with MIL-STD-883B, Bellcore TR-NWT-000078, ANSI/IPC J SF-818

• Meets the solderability parameters tested by the Singapore Institute of Standards and Industrial Research (SISIR)

| Item no. | WL83930 |

| Manufacturer | CHEMTRONICS |

| Manufacturer article no. | SW60-3-10 |

| Length | 3000 mm |

| Width | 2 mm |

| Sales unit | 1 rolls |

| Content unit | 1 rolls |

| Colour | green |

| ESD compliant | yes |

| GPSR manufacturer data | Chemtronics, ITW Contamination Control Electronics Saffierlaan 5 NL-2132 Hoofddorp www.chemtronics.com |

€10.94

Available soon

Item No.WL83930